Polycarbonate Baseplate

Polycarbonate Baseplate

Product Details

- Our Range

- Standard Profile

- Physical

- Installation

- Cleaning & maintenance

| Colour | Clear Transparent, Clear Embossed (as per requirements) |

| Thickness | 1.8mm to 3mm |

| Standard Width | 1070 (Can be Customised) |

| Standard Length | 1700mm (Can be Customised) |

| Light Transmission | 90%(clear) |

| Options | One Side UV, Both Side UV |

| Specials | Anti fog & Solar Control Option Available |

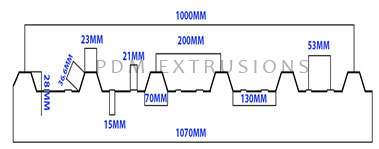

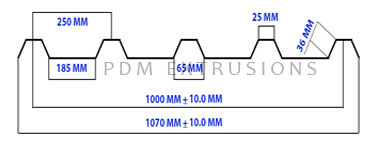

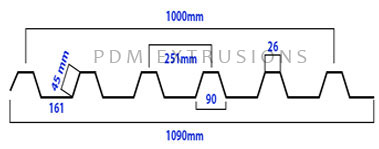

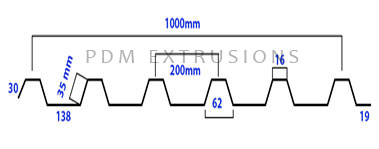

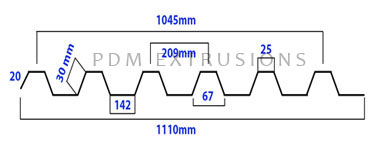

Model No. - PDMBP01/02 |

Model No. - PDMBP03 |

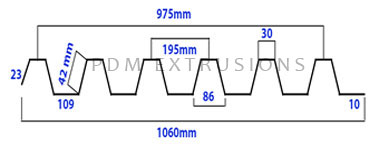

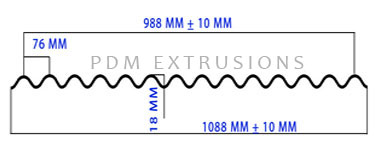

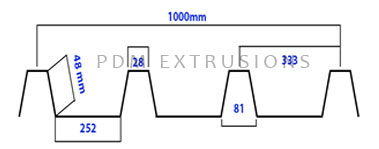

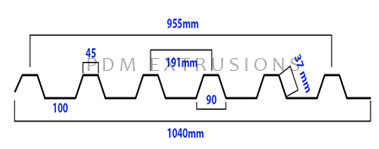

Model No. - PDMBP04/05 |

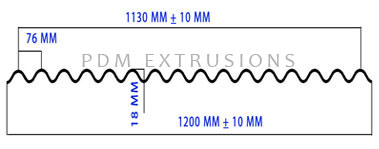

Model No. - PDMBP06 |

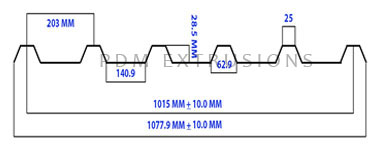

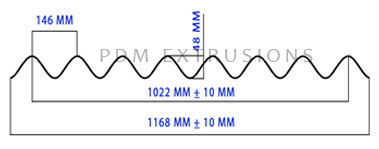

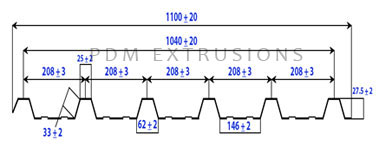

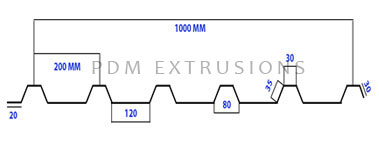

Model No. - PDMBP07 |

Model No. - PDMBP08 |

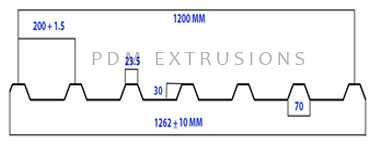

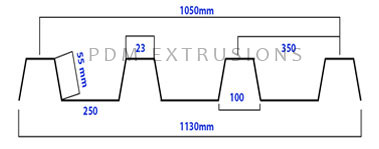

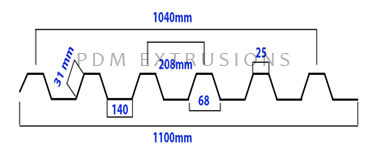

Model No. - PDMBP09 |

Model No. - PDMBP10 |

Model No. - PDMBP11 |

Model No. - PDMBP12 |

Model No. - PDMBP13 |

Model No. - PDMBP14 |

Model No. - PDMBP15 |

Model No. - PDMBP16 |

Model No. - PDMBP17 |

Model No. - PDMBP18 |

Model No. - PDMBP19 |

Model No. - PDMBP20 |

| PROPERTIES TEST | METHOD VALUE UNITS | VALUE | VALUE | |

| Mechanical | Tensile strength at yield | DIN 53455 | >60 | MPa |

| Tensile strength at break | DIN 53455 | >70 | MPa | |

| Elongation at yield | DIN 53455 | 6--8 | % | |

| Elongation at break | DIN 53455 | >100 | % | |

| Modulus of elasticity | DIN 53457 | >2300 | MPa | |

| Charpy notched impact strength | DIN 53453 | >50 | kJ/m2 | |

| Physical | Specific gravity | DIN 53479 | 1.2 | g/cm3 |

| Refractive index nD5 | DIN 53491 | 1.586 | ||

| Water absorption, 4h @ 23°C | DIN 53495 | 0.35 | % | |

| Water permeability (thickness 1mm) | DIN 5322 | <2.28 | g/m2 | |

| Thermal | Softening temperature - Vicat ‘B’ | DIN53460 | 148 | °C |

| Deflection temperature (load 1.81MPa) | DIN53461 | 142 | °C | |

| Linear thermal expansion | DIN53752 | 6.8x10-5 | m/m.K | |

| Thermal conductivity | DIN52612 | 0.2 | W/m.K | |

| Maximum service temperature | Permanent 100 | °C | ||

| no loading | Short term 130 | °C | ||

Installation Guideline for Polycarbonate Baseplate & Turbo Ventilator

- 1. Safety Precautions:

- 2. Tools and Materials Required:

- 3. Preparation:

- 4. Baseplate Installation:

- 5. Turbo Ventilator Installation:

- 6. Final Steps:

Personal Protection: Wear gloves, safety glasses, and protective clothing during installation.

Work Area: Ensure the installation area is clear of debris and hazards.

Tools: Measuring tape, drill, screwdriver, utility knife, sealant gun, and a circular or jigsaw.

Materials: Polycarbonate baseplates, turbo ventilators, screws, washers, sealant, and flashing

Measure and Mark: Determine the precise locations for the baseplates and ventilators on the roof. Mark these positions accurately.

Acclimatization: Allow polycarbonate baseplates to adjust to ambient temperature if stored in a different environment before installation.

Cutting: If necessary, cut the polycarbonate baseplate to the required size using a sharp circular or jigsaw blade. Leave a small gap (around 5mm) for thermal expansion.

UV Protection: Identify the UV-protected side of the baseplate and ensure it faces outward for optimal protection.

Placement: Position the baseplate on the roof, ensuring it aligns with the metal panels or other surfaces.

Drilling and Fastening: Drill holes at the marked points, allowing for thermal expansion by making the holes slightly larger than the screws. Secure the baseplate with appropriate screws and washers. Do not overtighten to avoid cracking.

Sealing: Apply a compatible silicone sealant around the edges for additional weatherproofing, if necessary.

Positioning: Place the turbo ventilator on top of the installed baseplate, ensuring proper alignment with the pre-cut hole in the baseplate.

Fastening: Secure the turbo ventilator to the baseplate using screws and washers. Ensure that it is tightly secured but not overly tightened.

Sealing: Apply sealant around the base of the ventilator where it meets the baseplate to prevent water infiltration.

Check for Stability: Ensure both the baseplate and turbo ventilator are securely fastened and stable.

Remove Protective Film: Carefully peel off any protective film from the baseplate and ventilator once installation is complete.

Inspection: Inspect the installation to ensure there are no gaps, loose fasteners, or unsealed edges.

Cleaning and Maintaining Polycarbonate Baseplate & Louvers

- 1. Regular Cleaning:

- 2. Avoid Harsh Chemicals:

- 3. Stubborn Stains and Dirt:

- 4. Inspection and Maintenance:

- 5. UV Protection Maintenance:

- 6. Turbo Ventilator Care:

Materials Needed: Soft cloth or sponge, mild soap (dish soap), and lukewarm water.

Process: Mix a mild soap solution with lukewarm water. Use a soft cloth or sponge dipped in the solution to gently clean the polycarbonate baseplates and turbo ventilators. Avoid using abrasive materials that could scratch the surfaces.

Rinsing: Thoroughly rinse with clean water to remove any soap residue. Dry with a soft, lint-free cloth to prevent water spots and streaks.

Prohibited Cleaners: Do not use ammonia-based cleaners, alcohol, or solvents, as these can damage the polycarbonate surface and cause clouding or cracking.

Safe Options: Stick to the mild soap and water solution for routine cleaning to maintain the integrity and appearance of the polycarbonate.

Tough Stains: For tougher stains or stuck-on dirt, use a diluted solution of white vinegar and water. Apply with a soft cloth and gently scrub the affected area.

Rinsing: Rinse thoroughly with clean water afterward to remove all residues.

Regular Checks: Periodically inspect the baseplates and turbo ventilators for signs of wear, damage, or loosening.

Tightening and Sealing: Ensure all screws and fasteners are securely tightened, and reapply sealant if necessary to maintain weatherproofing.

Scratch Prevention: Be careful when working around polycarbonate surfaces to avoid dragging sharp objects or abrasive materials across them, which could cause scratches.

Film Integrity: Ensure that the UV-protective coating remains intact. Avoid using abrasive materials that might strip the UV protection layer from the polycarbonate baseplates.

Replacement: If you notice significant yellowing or damage to the UV layer, consider replacing the baseplate to maintain its protective properties.

Lubrication: If your turbo ventilator has moving parts, such as bearings, lubricate them periodically with a manufacturer-recommended lubricant to ensure smooth operation.

Debris Removal: Keep the ventilator clear of debris that could obstruct airflow. Regularly check and clean to prevent blockages.

Key Features & Benefits

- High Impact Resistance: Perfect for safety barriers and riot shields.

- Exceptional Light Transmission: Bright interiors with UV protection.

- Superior Fire Performance: Self-extinguishing, minimal smoke emission.

- Lightweight for Easy Handling: Simplifies installation and manoeuvrability.

- Versatile Design Flexibility: Cold-bendable for creative architectural designs.

- UV Protection and Weatherability: Shields from sun damage, maintains clarity.

- Longevity and Low Maintenance: Resists yellowing and degradation over time.

- Durable in Harsh Conditions: Withstands rain, hail, snow, and extreme temperatures.

Application

Industrial Buildings

Greenhouses

Workshops

Commercial Roofs

Agricultural Structures

Airport Hangers

Sports Arenas

Residential Buildings