Polycarbonate Louvers

Polycarbonate Louvers

Product Details

- Our Range

- Standard Profile

- Physical

- Installation

- Cleaning & maintenance

| Colour | Clear Transparent, Clear Embossed (as per requirements) |

| Thickness | 1.8mm to 3mm |

| Standard Width | 1070 (Can be Customised) |

| Standard Length | 1700mm (Can be Customised) |

| Light Transmission | 90%(clear) |

| Options | One Side UV, Both Side UV |

| Specials | Anti fog & Solar Control Option Available |

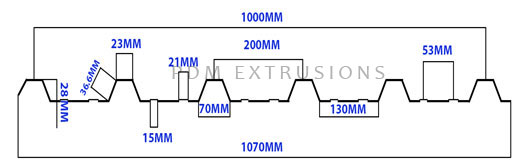

Model No. - PDMLP01 |

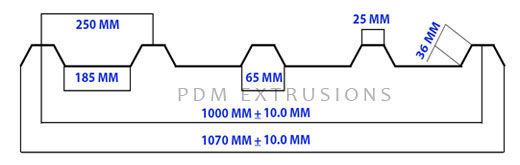

Model No. - PDMLP02 |

| PROPERTIES TEST | METHOD VALUE UNITS | VALUE | VALUE | |

| Mechanical | Tensile strength at yield | DIN 53455 | >60 | MPa |

| Tensile strength at break | DIN 53455 | >70 | MPa | |

| Elongation at yield | DIN 53455 | 6--8 | % | |

| Elongation at break | DIN 53455 | >100 | % | |

| Modulus of elasticity | DIN 53457 | >2300 | MPa | |

| Charpy notched impact strength | DIN 53453 | >50 | kJ/m2 | |

| Physical | Specific gravity | DIN 53479 | 1.2 | g/cm3 |

| Refractive index nD5 | DIN 53491 | 1.586 | ||

| Water absorption, 4h @ 23°C | DIN 53495 | 0.35 | % | |

| Water permeability (thickness 1mm) | DIN 5322 | <2.28 | g/m2 | |

| Thermal | Softening temperature - Vicat ‘B’ | DIN53460 | 148 | °C |

| Deflection temperature (load 1.81MPa) | DIN53461 | 142 | °C | |

| Linear thermal expansion | DIN53752 | 6.8x10-5 | m/m.K | |

| Thermal conductivity | DIN52612 | 0.2 | W/m.K | |

| Maximum service temperature | Permanent 100 | °C | ||

| no loading | Short term 130 | °C | ||

Installation Guidelines for Polycarbonate Louvers

- 1. Safety Precautions:

- 2. Tools Required:

- 3. Preparation:

- 4. Mounting the Louvers:

- 5. Sealing (Optional):

- 6. Final Inspection:

☑ Wear protective gear, including gloves, safety glasses, and long sleeves.

☑ Ensure the installation area is clear and stable.

☑ Measuring tape, drill, screws, screwdriver, and sealant (optional).

☑ A fine-toothed saw or shears for cutting louvers to size.

☑ Measure the installation area accurately.

☑ Cut the louvers to fit the specific dimensions, if necessary.

☑ Identify the UV-protected side, which should face outward.

☑ Position the louvers in place, aligning them with the structure.

☑ Drill holes through the louver and support frame, ensuring the holes are slightly oversized to allow for thermal expansion.

☑ Secure the louvers with appropriate fasteners, being careful not to overtighten

☑ Apply a compatible sealant around the edges to enhance weatherproofing and prevent air or water infiltration.

☑ Check the installation for stability and proper alignment.

☑ Remove any protective film from the louvers

Cleaning and Maintenance of Polycarbonate Louvers

- 1. Regular Cleaning:

- 2. Avoid Harsh Chemicals:

- 3. Tough Stains:

- 4. Scratch Prevention:

- 5. Additional Tips:

☑ Clean your polycarbonate louvers periodically to remove dirt, dust, and debris.

☑ Use a mild soap solution mixed with lukewarm water.

☑ Wipe the louvers gently with a soft cloth or sponge, and rinse thoroughly with clean water to remove any soap residue.

☑ Dry the louvers with a lint-free cloth to prevent streaks.

☑ Do not use abrasive cleaners, solvents, or harsh chemicals, as these can damage the surface of the polycarbonate louvers.

☑ Stick to mild, non-abrasive cleaning agents.

☑ For stubborn stains, use a diluted solution of white vinegar and water.

☑ Apply the solution with a soft cloth, gently scrubbing the stained area, and rinse thoroughly with clean water.

☑ Avoid dragging sharp or heavy objects across the louvers to prevent scratches.

☑ Handle the louvers with care during cleaning and maintenance.

☑ Regular inspection of the louvers for any damage or wear is recommended.

☑ Replace any damaged louvers promptly to maintain the integrity and functionality of your installation.

Key Features & Benefits

- High Impact Resistance: Perfect for safety barriers and riot shields.

- Exceptional Light Transmission: Bright interiors with UV protection.

- Superior Fire Performance: Self-extinguishing, minimal smoke emission.

- Lightweight for Easy Handling: Simplifies installation and manoeuvrability.

- Versatile Design Flexibility: Cold-bendable for creative architectural designs.

- UV Protection and Weatherability: Shields from sun damage, maintains clarity.

- Longevity and Low Maintenance: Resists yellowing and degradation over time.

- Durable in Harsh Conditions: Withstands rain, hail, snow, and extreme temperatures.

Application

Industrial Buildings

Greenhouses

Workshops

Commercial Roofs

Agricultural Structures

Airport Hangers

Sports Arenas

Residential Buildings